History of The Combination Pot Still:

The combination pot still, also known as the hybrid still, is a relatively modern invention compared to the traditional pot still with a column still.

The origins of the combination still can be traced back to the early 20th century, when distillers began experimenting with ways to combine the advantages of both pot stills with column stills. One of the early pioneers of the combination still was Aeneas Coffey, an Irish distiller who invented the Coffey still in 1830, which was an early form of the column still, the more plates the higher the purity when it comes to the Master spirit

However, it was not until the 1970s and 1980s that the combination still became more widely used in the industry. The rise of craft distilling and a growing interest in producing high-quality, small-batch spirits led to a renewed interest in the traditional pot still, as well as a desire to increase efficiency and output.

By combining the pot still columns still into one unit, distillers were able to produce a wider range of spirits, with a simple by-pass while also improving the efficiency and consistency of their operations. Today, the combination still is commonly used by craft distillers and small-batch producers to create unique and high-quality spirits, such as artisanal whiskey, brandy, and gin.

Why Distillers and Craft Beer Makers/ Breweries Use Combination Pot Stills:

A combination pot still is typically used for making certain types of beer, such as strong Belgian-style ales or barleywines however, if a brewer is interested in making distilled spirits from their beer, a combination pot still can be a useful tool. It allows for the distillation of high-proof spirits from the fermented beer, while still retaining the unique flavor profile of the original beer.

By using a combination pot still, a craft brewer can produce a range of spirits from their beer, including whiskey, brandy, and gin. The pot still section allows for the retention of the unique flavors and aromas of the beer, while the column still section allows for the production of higher-proof spirits. This can be a useful way to diversify a brewery’s product line and offer a unique and distinctive product to customers while adding SKUs to their operation.

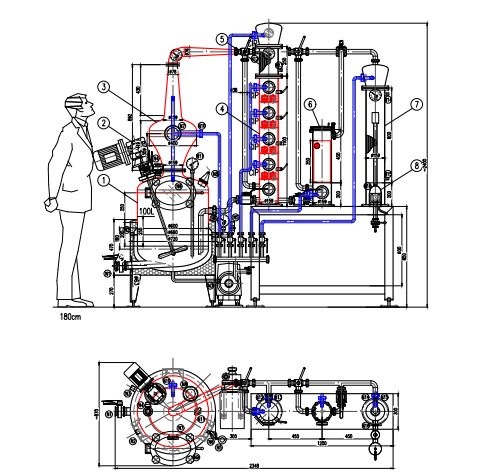

A combination pot still, also known as a hybrid still, is a type of distillation equipment that combines elements of both pot stills and column stills.

Pot stills are traditionally used to produce spirits such as whiskey and brandy. They are made up of a simple, large copper or stainless steel pot that is heated, and the resulting vapors are collected and condensed into a distilled liquid.

Column stills, on the other hand, are used to produce high-proof neutral spirits such as vodka and gin. They are made up of a tall column with multiple trays or plates that the vapor passes through, allowing for more efficient separation of alcohol from other impurities.

A combination pot still combines the simplicity and flavor profile of a pot still with the efficiency and higher-proof output of a column still. It typically has a pot still base with a column still section above it, allowing for the distiller to switch between the two methods of distillation depending on the desired outcome. This allows for a greater range of spirits to be produced on the same still.

Why Are Combination Pot Stills Versatile?

Combination pot stills are versatile because they allow for a greater range of spirits to be produced on the same still, as well as the ability to switch between different distillation methods.

With a combination still, a distiller can produce a range of spirits, from high-proof neutral spirits like vodka and gin to flavorful and complex spirits like whiskey and brandy. This versatility is due to the combination of the pot still and column still sections of the equipment.

The pot still section allows for the distillation of flavorful, aromatic spirits that retain the character of the original mash or wash, while the column still section allows for the production of high-proof spirits with a smoother, more refined flavor profile. By switching between the two methods of distillation, a distiller can create a wide range of spirits with varying flavor profiles and alcohol content.

Furthermore, combination pot stills are often designed with adjustable columns and plates, allowing for greater control over the distillation process. This allows distillers to fine-tune their production process and create unique, high-quality spirits that stand out in a crowded market.

Overall, combination pot stills are versatile tools that allow for greater creativity and experimentation in the production of distilled spirits, making them popular among craft distillers and small-batch producers.

Advantages of Distilling Alcohol In Small Batches:

There are several advantages to distilling alcohol in small batches, including:

Quality Control: With small batch distilling, a distiller can closely monitor the entire process and make adjustments as needed to ensure the highest possible quality of the final product.This is achieved via what we call “Bench Marking”

Creativity and Experimentation: Small batch distilling allows for more experimentation and creativity in the production process, as distillers can try out new recipes and techniques without the pressure of large-scale production.

Consistency: Small batch distilling can result in more consistent batches, as each batch is closely monitored and adjusted as needed to ensure that the final product meets a high standard of quality.

Flexibility: Small batch distilling allows for greater flexibility in terms of the types of products that can be produced. Distillers can produce a wider variety of spirits, experiment with different flavors and techniques, and respond more quickly to changing market trends.

Distinctiveness: Small-batch distilling can result in unique, high-quality spirits that stand out in a crowded market. By producing small batches with carefully selected ingredients and precise attention to detail, distillers can create distinctive products that appeal to discerning customers.

Advantages of Distilling Craft Beer Into Small Batch Distilled Products:

There are several advantages to making craft beer in small batches, including:

- Quality Control: With small batch brewing, the brewer can closely monitor the entire process and make adjustments as needed to ensure the highest possible quality of the final product. This can result in more consistent batches and higher-quality beer.

- Creativity and Experimentation: Small-batch distilled products allow for more experimentation and creativity in the brewing process, as brewers can try out new recipes and techniques without the pressure of large-scale production. This can result in unique and interesting Spirits that stand out in a crowded market.

- Freshness: Small-batch product allows the spirits to be consumed fresher than larger-scale production on an unaged Sku like Vodka & Gin. Since the spirits are produced in smaller quantities, they can be sold and consumed more quickly, resulting in a fresher product for the consumer.

- Cost-Effectiveness: Small-batch spirits can be more cost-effective than large-scale production, as it requires less equipment and space. This allows smaller distilleries to operate on a smaller budget and still produce high-quality Spirits.

- Community Involvement: Small-batch distilleries often attract a loyal following of customers who appreciate the attention to detail and quality of the Spirit. This can create a sense of community and support for the brewery, which can be beneficial for business growth and sustainability.

Overall, combination pot stills offer a range of benefits to distillers, including versatility, flexibility, and efficiency. These advantages can be especially important for craft distillers and small-batch producers looking to create unique and high-quality spirits that stand out in a competitive market. In addition, small-batch brewing offers numerous advantages over large-scale production, making it an attractive option for craft brewers, craft distillers, and those looking to produce high-quality, distinctive beers and spirits.